These are mixed Bifunctional reactive dyes where Vinyl Sulphone group is linked to chromophore through a mono chloro triazine group as a bridge link. They are applicable on cellulosic material at lower dyeing temperature of 60oC. The main features of 'Bi-functional' dyes are as under :

i) The dye-fibre bond between Vinyl Sulphone group and cellulose is stable to acid hydrolysis, so that stability of dyed goods in industrial acidic atmosphere is very good with the time lapse.

ii) The dyes which are not fixed during the dyeing process can be washed off easily because the hydrolysed dye has low substantivity and thus there is a little risk of staining of adjacent whites.

iii) Excellent levelling properties.

iv) Better reproducibility in dyeings.

v) High exhaustion and high fixation efficiency.

vi) Good all round fastness properties.

Bi-functional dyes are applicable on cellulosic materials by dyeing as well as printing methods.

(A) Dyeing Method with Supra Bi-functional dyes

They are applicable by both exhaust dyeing methods as well as pad-dyeing method.

i) Exhaust dyeing methods

Bi-functional dyes are applicable by exhaust dyeing methods in following different ways.

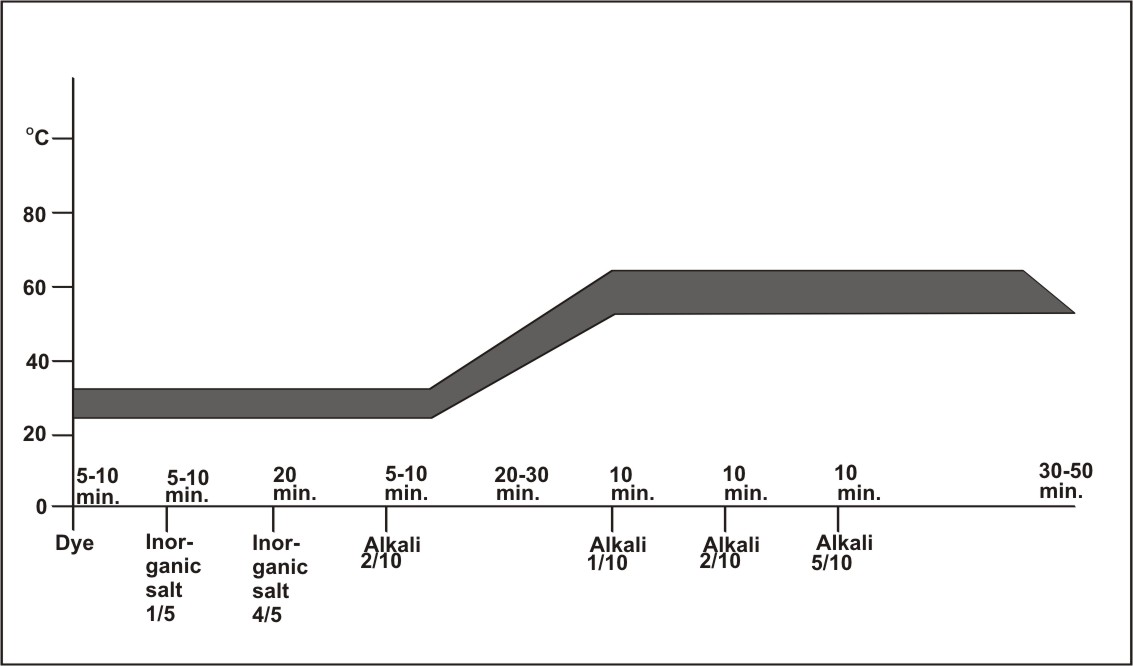

(a) Increase temperature method

Procedure

Set the dye-bath at 25oC with dye solution and carry out dyeing for 10 minutes. Then add half amount of salt and continue dyeing by raising temperature to 45oC in 10 minutes. Add remaining half the amount of salt at 45oC and rinse the temperature to 60oC for further 5 minutes and then add half amount of soda ash and continue dyeing for 10 minutes. Add the remaining half amount of soda ash and dyeing is continued for further 50 minutes at 60oC. The goods are then washed off.

Salt & Alkali requirements

| %Shade | Glaubers Salt gms/l | Soda Ash gms/l |

| 1.0 to 2.0 | 35 to 50 | 15 |

| 2.0 to above | 50 | 15-20 |

* For light shades of less than 1% quantity of Glauber's salt & soda ash to be reduced appropriately.

Temperature-increasing method

This method gives better levelness when it is difficult to get level dyeing.

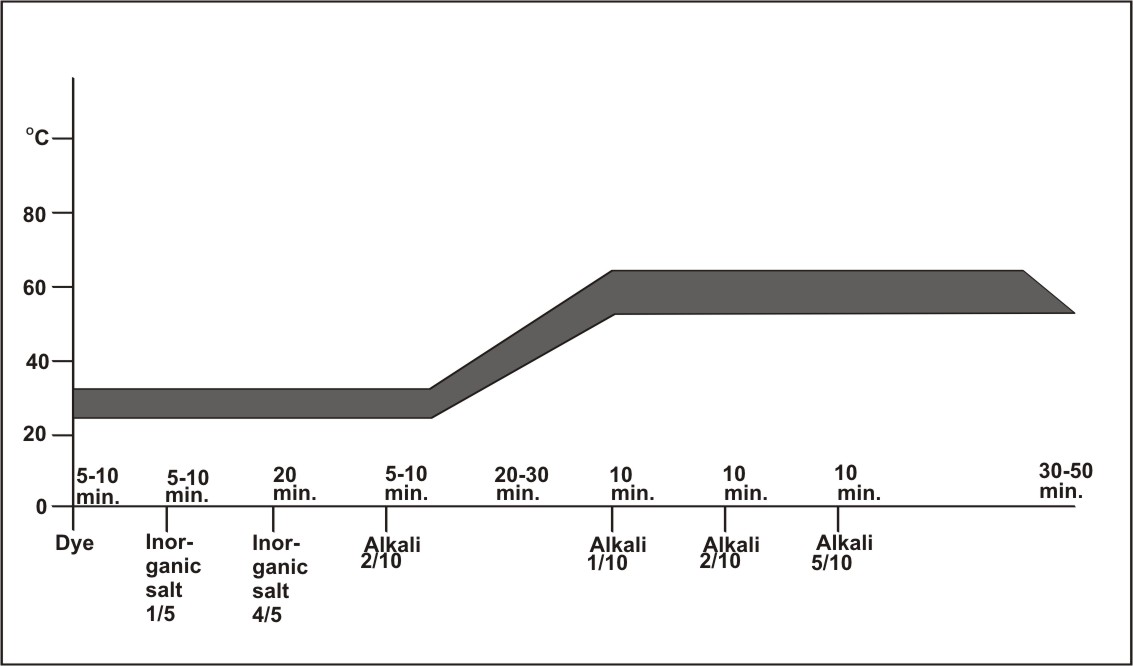

(b) Constant temperature method

Procedure

Set the dye-bath at 60oC with the dye solution. carry out dyeing at 60oC for 10 minutes. Then add Salt at 60oC and continue dyeing for 25 minutes. Add half the amount of Soda ash and continue dyeing for 10 minutes. Then add remaining half amount of Soda ash and continue dyeing for further 50 minutes, at 60oC. The goods are then washed-off.

Salt & alkali requirements : same as (8)

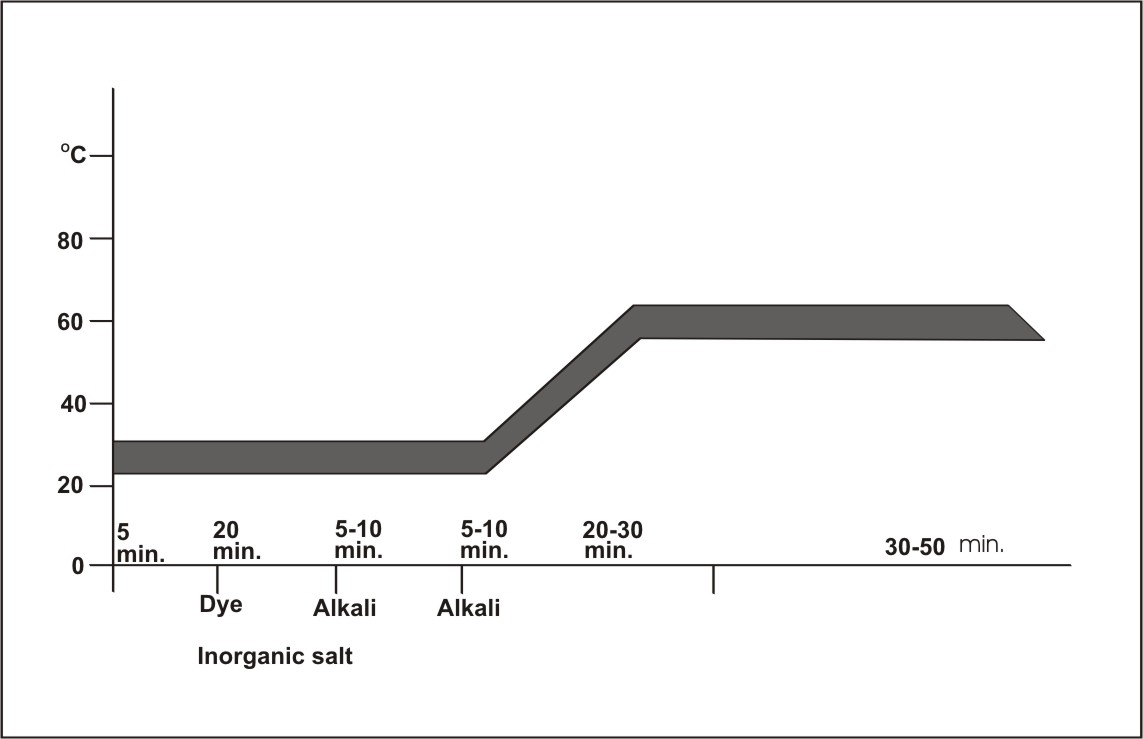

(c) All-in Method

This method is particularly suitable for unmercerised cotton to produce deep shades. Moreover this method is applicable to Vinyl sulphone dyes and hence combination of Vinyl sulphone dyes is possible.

Process

Set the dyebath at 20-30oC. Add Salt and continue dyeing for 5-10 minutes. Then add dye solution and continue for 15-20 minutes. Now add half amount of alkali and dye for 5-10 minutes. Add remaining half amount of alkali and continue for further 5-10 minutes.Then raise temperature to 50-60oC in 20 minutes(1-5oC rise/minutes) and continue dyeing at 50-60oC for 45-60 minutes.

"New all-in" method

The "new all-in" method with Bi-functional Dyes gives an ideal rate of dyeing in terms of levelness and reproducibility even after the addition of alkali, but it is necessary to take into account the type of dyeing machines and the form of materials to be dyed.

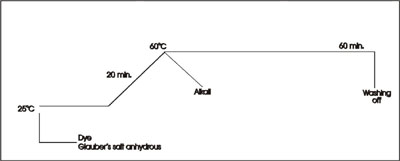

Suitability for cheese dyeing

The Suitability for cheese dyeing was measured as follows :

Dyeing depth : 3.0% o.w.f.

Glauber's salt anhydrous : 50 g/l

Soda Ash : 20 g/l

Good : Liquor ratio : 1:20

Temperature and time : 60oC, 60 minutes

ii) Pad-dyeing method

(a) Pad-batch method

| Padding Liquor | Dyestuff | X parts |

| Urea | 50 parts | |

| Water | remaining | |

|

Sodium Silicate (134-142oTw) Na2O : SiO2 : 1:2.1 |

85 parts | |

| Caustic Soda 33% | 4 parts | |

| Total | 1000 parts |

Procedure

The goods are padded in the above padding liquor and batched on a plastic sheet and kept for about 20 hours and then wahed. However, all dyes are not suitable by this method.Hence proper selection is to be carried out.

It is also applicable by using Caustic Soda + Glauber's Salt in place of sodium silicate + Caustic Soda as alkali agent in above padding liqour.This is particularly important when dyeing thick fabrics such as corduory, because removal of silicate is very difficult.

Caustic Soda (40oBe) - 12 cc/litre

Glauber's Salt - 30 gms/litre

(b)Printing methods

Bi-functional dyes are applicable by various printing methods on cellulosic material, with the following advantages:-

1) Suitable for various method of printing with a high fixation degree.

2) Print paste containing alkali has superior storage stability.

3) A smaller amount of alkali is sufficient for dye-fixation.

(a) Print - Dry - Steam - Wash - Dry

(Bi-functional dye + alkali)

| Printing recipe | Dyestuff | 20 parts |

| Urea | 50 parts | |

| Water | 300 parts | |

| Sodium Alginate Paste | 400 parts | |

| Soda Ash | 10 parts | |

| Resist Salt | 10 parts | |

| Water | remaining | |

| Total | 1000 parts |

Procedure

The goods are printed with above print paste and dried.

The dried goods are then steamed for 7-10 minutes at 100-103oC in saturated steam and washed.

(b) Print - Dry - Pad - Batch - Wash

Bi-Functional dye without alkali (Sodium Silicate)

The goods are printed with alkali and dried.

The dried goods are then padded in a sodium silicate solution and covered with a plastic sheet and kept for 20-24 hours, and washed.

Washing off

To obtain optimum fastness properties a thorough and complete wash-off should be given to printed goods.The goods are first washed thorough in cold water and then in hot water. Then boil it for about 5 minutes with anionic detergent 1-2 parts/litre. Finally, rinse in cold water and dry. Wherever necessary a treatment with dye-fixing agent may be given with 2-5 parts/litre of final wash liquor.

| Key to Abbreviations : | |

| L = Low | |

| M = Medium | |

| H = High | |

|

V =Very High |

|

| + =Suitable | |

| (+) = Fairly Suitable | |

| - = Not Suitable |

Dischargeability : G = Good, F = Fair, P = Poor

Light : 1 to 8 in increasing order

Washing & other : 1 to 5 in increasing order

Y = Yellow

O = Orange

R = Red

V = Violet

B = Blue

Br = Brown

Bl = Black

G = Green