INTRODUCTION SHADE

CARDS

HE

dyes are suitable for dyeing cotton and other cellulosic materials. Tese dyes

possess significantly higher exhaustion and fixation efficiency which

results in appreciable cost reduction in comparison to convectional reactive

dyes. The high fixation and good build up are of particular importance

when dyeing polyester/ cellulosic blends where liquor : goods ratio is

quite high. Due to higher fixation of HE dyes, the drained and wash liquors

after dyeing contain much less quantity of unmixed dyes, i comparison

to conventional reactive dyes, which is of interset when pollution control

is a major concern to everybody. This facilitates quicker wash off and efficient

soaping. The improved stability of HE dyes gives improved batch to batch

consistancy. Exhaustion of HE dyes can be controlled by salt addition

and temperature to give level dyeing before alkali addition.

The other useful features of HE dyes are as under :

1. Excellent

build-up in high as well as low liquor : goods ratios.

2. The high fixation is of particular importance when

dyeing polyester/cellulose blend when liquor/ goods ratio is

quite high. Under the circumstances, conventional

reactive dyes show low dyeing efficiency and poor build-up.

3. Excellent reproducibility.

4. Wide applicability on yarn, piece material, loose

stock and garments.

5. Wide choice of equipment to suit a particular application.

Dyeing

Methods

Winch,

jet, package & Beam dyeing machines.

These dyes are specially designed for exhaust dyeing methods. The dyeing

method selection depends upon the type of substrate to be dyed and the

machinery to be used for dyeing.

|

Depth of shade |

Salt |

|||

|

(gm/l) |

Mercerised |

Soda

Ash |

Fixation

time |

|

|

Upto 0.1% |

10 |

5 |

10 |

30 |

|

0.11-0.30% |

20 |

10 |

10 |

30 |

|

0.31-0.50% |

30 |

20 |

10 |

45 |

|

0.51-1.0% |

45 |

30 |

15 |

45 |

|

1.01-2.0% |

60 |

40 |

15 |

45 |

|

2.01-4.0% |

70 |

55 |

20 |

60 |

|

Above 4.0% |

90 |

65 |

20 |

60 |

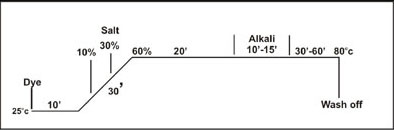

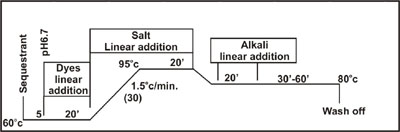

Method No. 1 :

Salt

addition in portions (Suitable for mercerised yarn)

This

process is recommended for non-circulating liquor machinery and it is suitable

for all depths of shade.

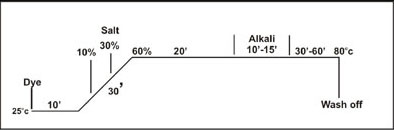

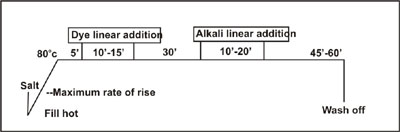

Method No. 2 :

Salt

addition at start (Suitable for unmercerised yarn)

This

method is recommended for machines with liquor circulation and it is suitable

for medium to heavy depth of shades.

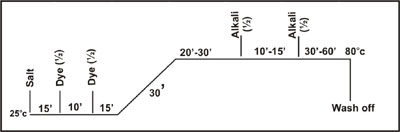

Method No. 3 :

Both

salt and alkali additionat start.

This

method is recommended for machines with liquor circulation, primarily for the

dyeing of medium - heavy binary combinations. It is suitable for unmercerised

cotton.

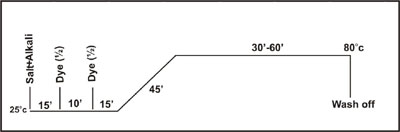

Method No. 4 :

(Dyeing

Pale Shades) (Garment

Dyeing)

This method is recommended for machines with microprocessor controlled

addition system for dyeing pale shades(less than 0.5% depth) and for all

shades on mercerised cotton & viscose packages.

Methods No. 5 :

Isothermal

Method (Dyeing Heavy Shades Garment)

This

method is recommended for machines with microprocessor controlled addition systems

for medium to heavy depths (> than 0.5% depth) on unmercerised cotton.

Dyeing

method for jigger machines

Due

to high temperature dyeing, the problems of off-shade selvedges or too pale

selvedges are often

encountered in dyeing with these machines. The following precautions hence

should be taken to avoid such

problems.

1) To use closed type jiggers so that a uniform temperature is possible

accross the width of fabric.

2) Batch the fabric evenly.

3) Maintain the dye bath at minimum of 85-90oC during salt stage.

4) Adjust the dye bath temperature to 85-90oC to ensure that fabric is

maintained at minimum 80oC during alkali addition stage.

Procedure

Set the dye bath at 90oC with resist salt 2 gms/l. Now add 1/2 amt.

of dye and run one end. Then add remaining 1/2 amt.& run an another

end. Maintain 80oC temp. continue to run for 2 ends. Now add 1/2 amount of soda

ash & run for another one end. Then add remaining 1/2 amount of soda

ash & run for another one end. Then run for

4 ends or more if required & wash. (1 end = 10 minutes) Dyeing Methods

for cotton / polyester Blend.

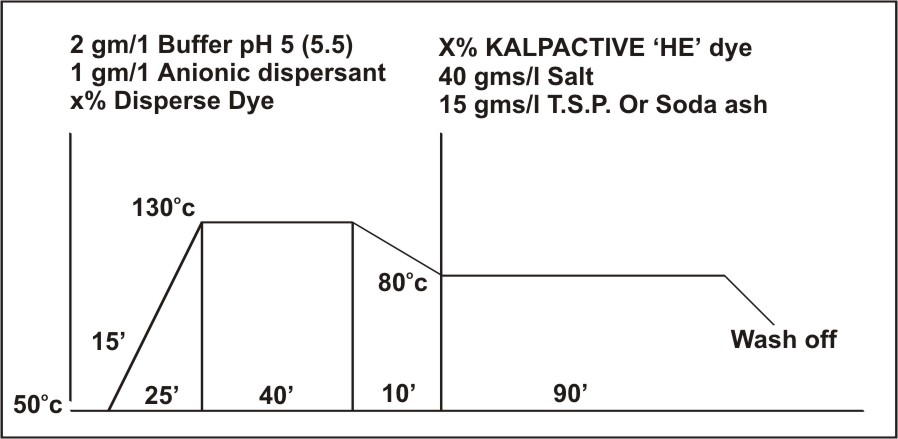

The one bath two stage dyeing method for polyester / cotton blend is applicable

on jet, beam or package dyeing

machines.

2

gm/l Buffer pH 5 (5.5) X%

KALPACTIVE 'HE' dye

1 gm/l Anionic dispersant 40

gms/salt

X% Disperse Dye 15

gms/l T.S.P. or soda ash

Salt and alkali requirements

|

Depth

of shades % on total |

Salt

|

Soda

Ash |

|

Upto 0.2% |

15 |

10 |

|

0.21-0.4% |

20 |

15 |

|

0.41-0.80% |

30 |

15 |

|

0.81-1.6% |

50 |

20 |

|

Above 1.6% |

70 |

20 |

Washing-off

procedure

In

order to obtain maximum wet-fastness properties, brightness and purity of shades

with consistent dyeing results,

it is essential to give a thorough 'soaping' to clear-off unreacted hydrolysed

dye from the dyed fabric.

The dyed fabric is rinsed repeatedly in cold water to remove most of the

alkali, salt and unfixed dye present and rinse again in warm water not

higher than 60oC. Then run in a bath containing:

Anionic

detergent

1-2

gms/litre for 15 minutes at the boil. Then rinse in warm water (up to 60oC)

and finally in cold water. The satisfactory results in washing-off, particularly

for piece goods, are obtained by employing an open soaper or perforated

Beam-washing machine. If such equipments are not available, conventional ones

like jig or winch may be used. For yarn in the hank from open-vat is employed

and for yarn in packaged from the package-dyeing machine itself used.

| Key to Abbreviations : | |

| L = Low | |

| M = Medium | |

| H = High | |

|

V =Very High |

|

| + =Suitable | |

| (+) = Fairly Suitable | |

| - = Not Suitable |

Dischargeability : G = Good, F = Fair, P = Poor

Light : 1 to 8 in increasing order

Washing & other : 1 to 5 in increasing order

Y = Yellow

O = Orange

R = Red

V = Violet

B = Blue

Br = Brown

Bl = Black

G = Green